Simulation of refrigerator water tank

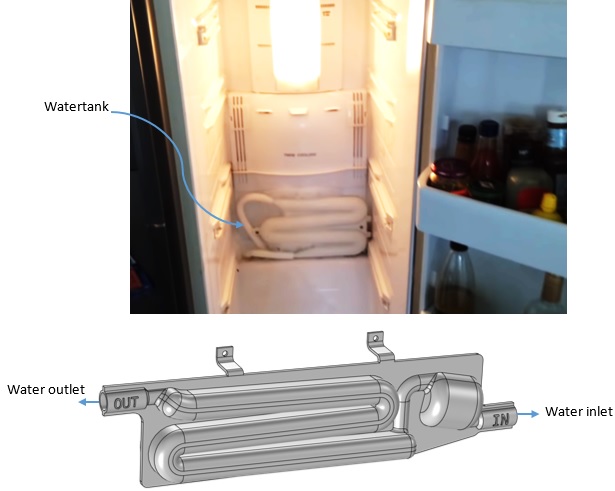

There are two types of water tank system in the refrigerator. One is a pipeless system and is manually filled with water. The other system has piping and fills the tank automatically. In this type of refrigerator, the water tank is located inside the refrigerator and at its rear end. The city tap water enters the tank, then it goes to the bottom of the refrigerator through the piping, and it rises again to the height of the refrigerator dispenser and is connected to the back of it. The performance of the water tank of this type of system is checked by simulation. In this simulation, the effect of pipes before and after the tank is also considered.

Physical phenomena in the model

Inside the tank, two scenarios are investigated. The first scenario is filling the tank with water. In this situation, the entire tank contains air, and the water pushes the air out when it enters the tank. This scenario includes the following physical phenomena:

- Two-phase flow: simply, a phase is one of the states of matter, which can be solid, liquid or vapor. Multiphase flow can include different states of a substance such as water and water vapor or, like this problem, it can consist of several different substances such as water and air. The remarkable point in multiphase physics is the non-mixing of phases and the existence of an interface between them.

- Turbulence: at high speeds and high Reynolds number, the flow leaves its laminar state and creates vortices.

- Water Hammer: is an increase in pressure or a wave that occurs in moving streams after a sudden stop or change in direction. This increase in pressure usually occurs when a valve in the flow path (water or gas) suddenly closes.

- The second scenario is when the tank is full of cold water and water with a higher temperature enters it from the piping system. In this scenario, the most important phenomenon is mixing cold and hot water and changing the temperature of the mixed water.

Design evaluation parameters by simulation

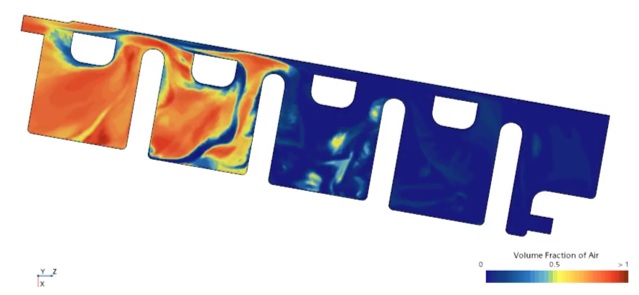

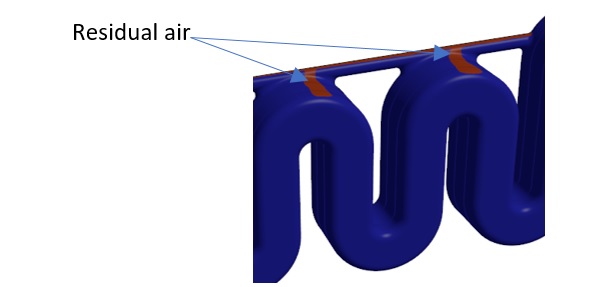

In the design of the refrigerator water tank, the low amount of turbulence and the absence of residual air in the tank is one of the most important design constraints during the initial water intake. If the air is trapped inside the tank, the volume of air is condensed and expands when the water intake is stopped and the water pressure is removed. This expansion causes water to spray from the refrigerator dispenser after stopping water intake. Also, remaining air and the pressure created by it can damage the refrigerator equipment.

In the case that the tank is filled with water and then hot water enters it, it is necessary to have a geometrical design in such a way that the incoming water pushes out the water in the tank and its mixing rate is at a minimum. The less mixing, the more cold water volume can be received from the tank.

Description of the simulation model

The purpose of this simulation is to check how the tank is filled with water and also how the cold and hot water mix in the tank. The VOF model is used to check the initial filling of the tank. When water enters the tank, the movement of the water-air interface is investigated. In this situation, the presence of water or air in each mesh cell is determined by a number between zero and one, where the number one indicates the presence of pure air and the number zero indicates the presence of pure water in the cell. Due to the fact that the flow rate of the incoming water, its speed and pressure have a significant effect on the initial filling of the tank and subsequent watering, it is necessary to know their values. It should be noted that the speed and pressure of the incoming water has a serious effect on how the water enters the tank and how air remains or leaves the tank. Therefore, the possible range of speed and pressure should be checked in the simulation. Also, considering that the pipes before and after the tank play a decisive role in the pressure drop of the incoming water from the beginning of the system, the effect of this equipment is determined by tests to determine the water pressure at different points of the system. Finally, by obtaining the pressure difference at the inlet and outlet of the tank, the appropriate initial values are determined.

After the tank is filled and in subsequent water intakes, to check the effect of mixing, it is necessary to know the temperature of the water inside the tank and the inlet water. Although the temperature may change in different situations, it is simplified by determining the acceptable range.

The function of the simulation model

Considering that the geometric design of the tank is very important for production, multiple designs can be tested by simulation without spending the cost of making a prototype. In addition, the exact behavior of water and the movement of the interface between water and air inside the tank cannot be seen in experimental tests, while with the help of simulation, all the moments of water intake can be observed graphically and at desired points of the tank. In the performed simulations, several different plans have been examined and suggestions have been made to optimize the plan.